Quality

Highest quality molded foam products

Through daily TS16949 practices and annual hands-on training, we have developed highly evolved best practices that are applied to each and every project. Our team ensures that risk and feasibility are always extensively assessed prior to the development of any products. And once production is underway, our designs are continually reviewed by highly skilled engineers to ensure compliance, timely deliverables, and that all customer expectations are met and/or exceeded.

Highest quality molded foam products

Through daily TS16949 practices and annual hands-on training, we have developed highly evolved best practices that are applied to each and every project. Our team ensures that risk and feasibility are always extensively assessed prior to the development of any products. And once production is underway, our designs are continually reviewed by highly skilled engineers to ensure compliance, timely deliverables, and that all customer expectations are met and/or exceeded.

CUSTOM MOLDED FOAM FOR EVERY FUNCTION

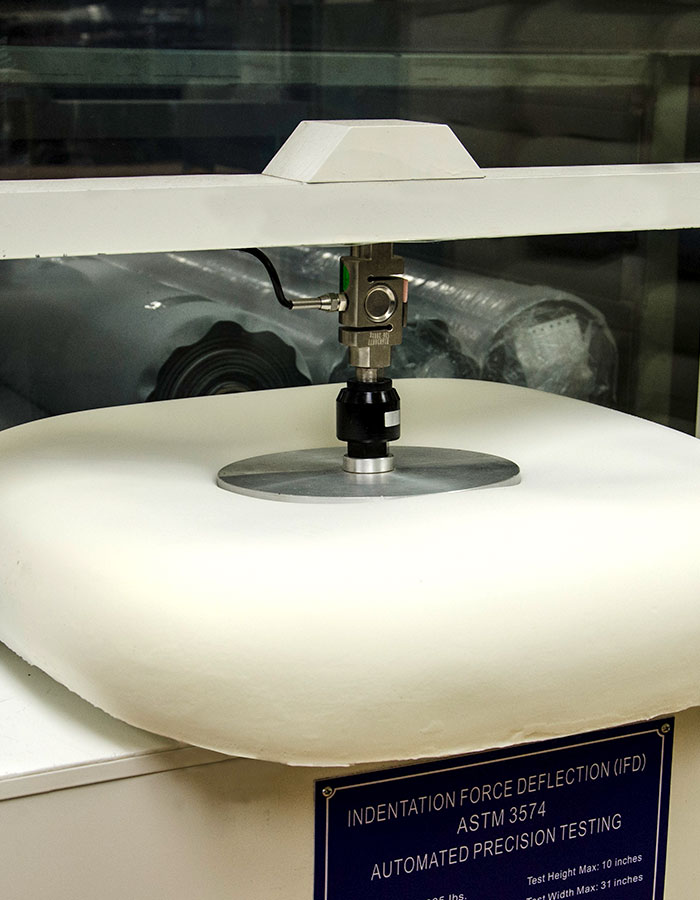

FOAM SOFTNESS AND FIRMNESS

High on our customer’s list of importance is the firmness and feel of the foam part. TMI uses the ASTM D3574 IFD Foam Compression Testing Method. Pressure in pounds is applied to the polyurethane foam part compressing it down 25% from its original height. This results in a corresponding number called the “IFD”, or indentation force deflection. This number can then be customized higher (more firm) or lower (more soft) to meet the desired needs of our clients.

Get In Touch

There’s no such thing as too much information when it comes to finding the perfect solution.

To request a quote, ask a question, or leave a comment, simply send us a message and our team will be happy to assist you.